EVO-10

Fuel prefilter

The Separ Filter EVO-10 is a non-ferrous fuel water separator designed to be installed in-line of the fuel system to protect engines from free water and particulate present in diesel fuel.

• High separation efficiency with minimal pressure drop

• Easy to install

• Service and environment friendly

• Flow rate max. 10 l/min

• Compact design with minimal weight (3.5 LBS | 1.1 Kg)

EVO-10 offers:

- Construction

- Transportation

- Off-Road Machinery

- Agricultural Applications

- Trucking

Equipment variant

EVO with water in fuel sensor

Sizing By Flow Rate

The EVO-10 filter from the SWK-2000 Filter Series typically has a flow rate that depends on its specific application and configuration. Generally, the flow rate can vary based on the type of fluid being filtered and the operating conditions.

For a standard diesel fuel application, the flow rate for an EVO-10 filter is usually around 2.63 gallons per minute (GPM) or 10 liters per minute (LPM).

Other Versions & Accessories Available

- Electric heating system

- Manual Priming Pump

- Contamination detection

- Water-in-fuel sensor

- Non-ferrous metal-free design

Fields of Application

- Construction machinery, forklift trucks

- Mining machinery

- Buses, trucks, municipal vehicles

- Agricultural machinery

- Generators

- Compressors, stationary machines

- Crane trucks

- Rail vehicles

- Vessels

Quality & Certificates

All products made by Willibrord Lösing Filterproduktion GmbH are designed & Made By Germany

All products made by Willibrord Lösing Filterproduktion GmbH are designed to meet highest market requirements.

They are permanently tested for workmanship, functionality and durability throughout the entire development process, from the design phase to production. In addition to institutional certifications, our own strict testing standards form the basis for a consistently high level of quality.

Our distribution organization, built up over decades, guarantees fast and reliable supply chains and services.

They are permanently tested for workmanship, functionality and durability throughout the entire development process, from the design phase to production. In addition to institutional certifications, our own strict testing standards form the basis for a consistently high level of quality.

Our distribution organization, built up over decades, guarantees fast and reliable supply chains and services.

The SWK has various approvals and certificates. Copies can be provided on request.

Below is a list of organizations that have carried out these tests.

- American Bureau of Shipping, ABS

- Bureau Veritas Type Approval Certificate, BV

- Germanischer Lloyd Type Approval Certificate, DNV/GL

- German Technical Department of Army Ship and Marine Weapons, WTD

- Kraftfahrtbundesamt Flensburg, KBA

- Lloyd Type Approval Certificate, LR

- Registro Italiano Navale, RINA

- Rheinisch-Westfälischer TÜV, RWTÜV

Product Technical Data

The data mentioned here represent the respective maximum upper limits.

Fuel type | Diesel, EN590 (others on request) |

Filter construction | Fuel prefilter and water separator with exchangeable filter element |

Material of the filter housing | Filter head and cover PA6.6 GF50 Bowl PA transparent |

Maximum overpressure | 1 bar |

Flow rate | max. 10 liters/minute |

Maximum amount of water | Approx. 0,250 liters without heater & Approx. 0,195 liters with heater |

Pore size of the filter elements: | 30 µm or 10µm |

Differential pressure loss: | < 30 mbar (filter element as good as new; diesel according to EN590; fuel temperature 20 °C) |

Temperature ranges | Storage: - 40°C to +85°C Operation - 40°C to +85°C |

Empty weight | approx. 1,1 kg without heater approx. 1,5 kg with heater |

Color | black (filter head) , Transparent (filter bowl) |

Maximum differential pressure at filter element | 300 mbar |

Differential pressure contamination limit: | 270 mbr |

The storage and operating temperatures are limited to a maximum of +85°C by the materials used with a safety reserve.

Flow Rates

10 lit/min - 600 lit/Hours

EVO-10

Single/ Duplex and Double Systems

Low weight

Compact Design & Material

Options

Water in fuel sensor

Main Functions of EVO-10

High separation Efficiency With Minimal Pressure Drop

Our patented filter technology creates a safe and efficient separation of water and other contaminates from the fuel. The large diameter of all internal cross sections and channels minimizes the pressure drop. Finest impurities and water droplets are efficiently trapped by the large surface area of pleated filter element.

Simple & Quick Maintenance

The filter operation is protected by an easy to remove cover. This will prevent dirt that could contaminate the fuel circuit when the filter lid is opened. The filter has been designed to allow element replacement / service without the use of tools.

Less weight due to compact design

Due to the use of most modern materials, we have reduced the volume and weight of the filter drastically, without loss of any efficiency or reliability.

Environmentally friendly

The filter is constructed from completely recyclable mate-rials. Moreover the element can be reused multiple times during the life of the filter, meaning waste disposal costs and hence the environmental burden will be minimized.

Optionally with Water-in-Fuel-Sensor

A filter fitted with the optional WiF-Sensor (Water-in-Fuel-Sensor) does not need to be regularly checked for water. If water is present in the fuel, the WiF-Sensor will activate an alarm to signal it should be removed by ope-ning the drain valve.

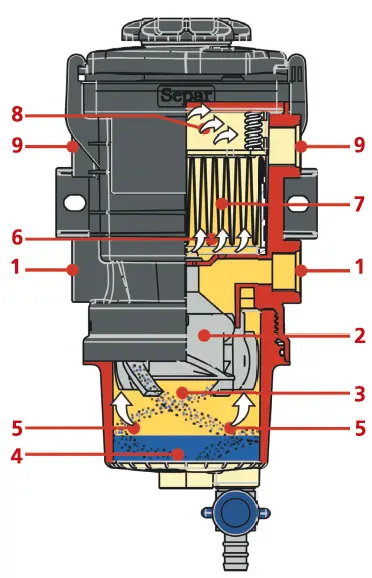

How It Work

1 - Fuel inlet

2- Rotational motion is induced in the fuel, while passing through the internal vanes.

3- The fuel exits the internal vane system and enters the filter bowl.

4- Due to the rotational energy, water and particulates separate from the fuel and settle at the bottom of the bowl.

5- The fuel is guided to the filter prechamber.

6- The large cross section of the prechamber results in the fuel flow velocity being reduced, allowing more particulate separation.

7- Suspended particulates and the finest water droplets are caught in the pleated media of the filter element.

8 - The cleaned fuel passes to the outlet chamber.

9 - Fuel outlet.

Fuel enters through either bottom port A or B. Plug off the inlet port that is not in use.

Installation

The filter has to be installed in the suction line (in between the tank and the fuel lift pump), however it does not matter whether the filter inlet is positioned above, level with, or below the maximum fuel level in the tank for the filter to function correctly. As a safety precaution we suggest installing a shut-off ball valve with full flow diameter between the fuel tank and the filter.

Simplex

The EVO-10 is a single filter assembly with a maximum flow rate up to 158 GPH or 600 LPH . The water-in-fuel sensor is optional, and recommended to send a signal when water must be drained from the bowl. The filter is compatible with engines that have a lift pump flow rate (not burn rate) that is equal to or less than 158 GPH or 600 LPH.

EVO-10 Single Filter

Simplex or Duplex

Looking at a typical marine customer as an example, if they had two engines on their boat, they would need a simplex filter for each engine’s fuel system. A simplex filter is one with a single body and a single path for the fuel to flow through. However, If the customer had a boat with a single engine, we would strongly recommend a duplex filer – this has two paths for the fuel to flow though, where only one is in use at any time. Should the customer experience fuel contamination in the twin engine boat, it is highly unlikely both fuel systems would block at the same time, in the single engine boat however; a simple movement of the duplex’s changeover lever and the second flow path becomes live. The first path is now clear for servicing, without having to stop the engine.

SWK-2000 Simplex Series

SWK-2000 Duplex Series

SWK-2000 Double Simplex Series

Flow Rates

From 5 lit/min to 130 lit/min

SWK-2000

Single/ Duplex and Double Systems

5-Stage

Filtration System

Options

Water Sensor, Gauge Indicator, Heater

To be successful your content needs to be useful to your readers.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.

Start with the customer – find out what they want and give it to them.